| Serial number | Section | Process Overview | Equipment advantages | Equipment | |||||||||

| 1 | Powder Cotton | The refined cotton/wood pulp (Cell) that has passed the inspection is sent to the cotton opening and crushing machine for crushing. After the crushed Cell passes through a 100-mesh sieve, it is blown into the transfer cotton bin by a fan. Finally, a specified number of sieved powdered Cells are put into the metering cotton bin to wait for cotton addition. | Lipu cotton powder machine: domestic substitution, performance exceeds the German imported NETZSCH cotton powder machine. Advantages: high cotton powder efficiency and strong stability during operation. |  | |||||||||

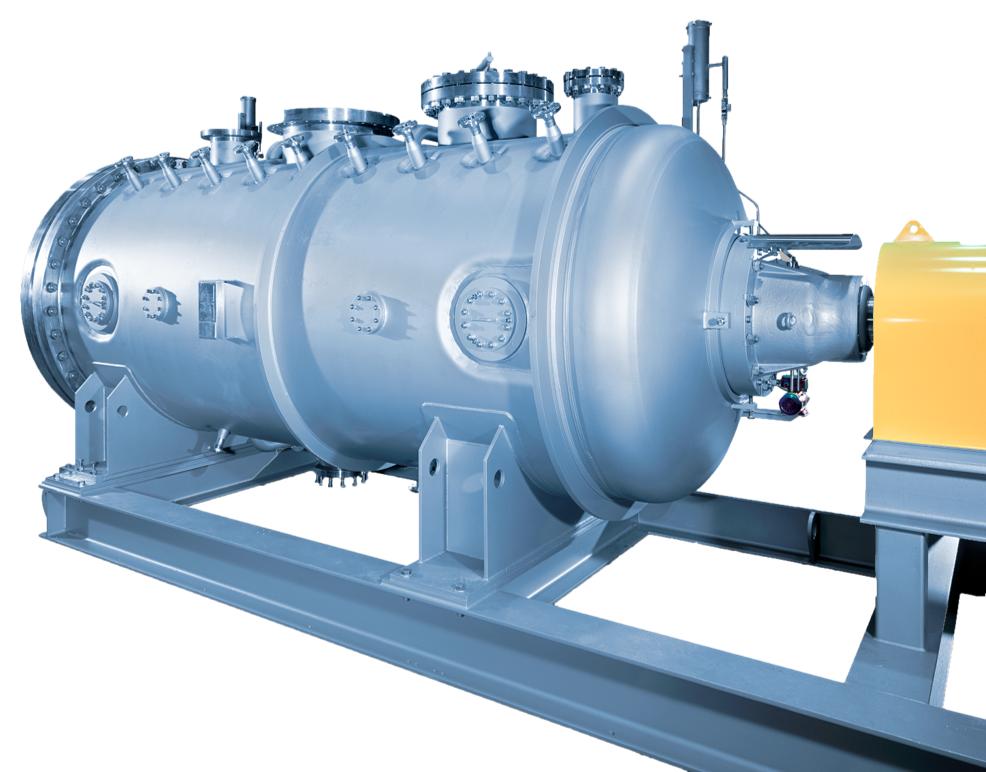

| 2 | Etherification | When the reaction section is operating normally, the cotton powder in the cotton powder metering bin is added to the etherification reactor by batch call, and the vacuum nitrogen replacement operation is carried out. According to the process parameter requirements, a certain amount of distillate and a certain concentration of sodium hydroxide are added in sequence; according to the product brand, etherifying agent propylene oxide or ethylene oxide and a certain amount of methyl chloride are added; the temperature, pressure and time of the reactor are controlled, the etherification reaction is carried out and the inert gas is exhausted after the stage reaction is completed. After the exhaust of the etherification inert gas is completed, a certain amount of methyl chloride is added to continue the reaction. After the reaction is completed, the reactor is depressurized at the first, second and third stages. After the pressure reaches the process requirements, sufficient brine or fresh hot water is introduced to flush the reactor and discharge the material into the paddle receiving tank. | Roediger horizontal etherification kettle: 1. Short reaction time (60% shorter reaction time than vertical etherification kettle). 2. 26m3 solvent: 200% higher capacity than vertical etherification kettle. 3. Uniform reaction: high reaction pressure and more uniform horizontal agitator. |  | |||||||||

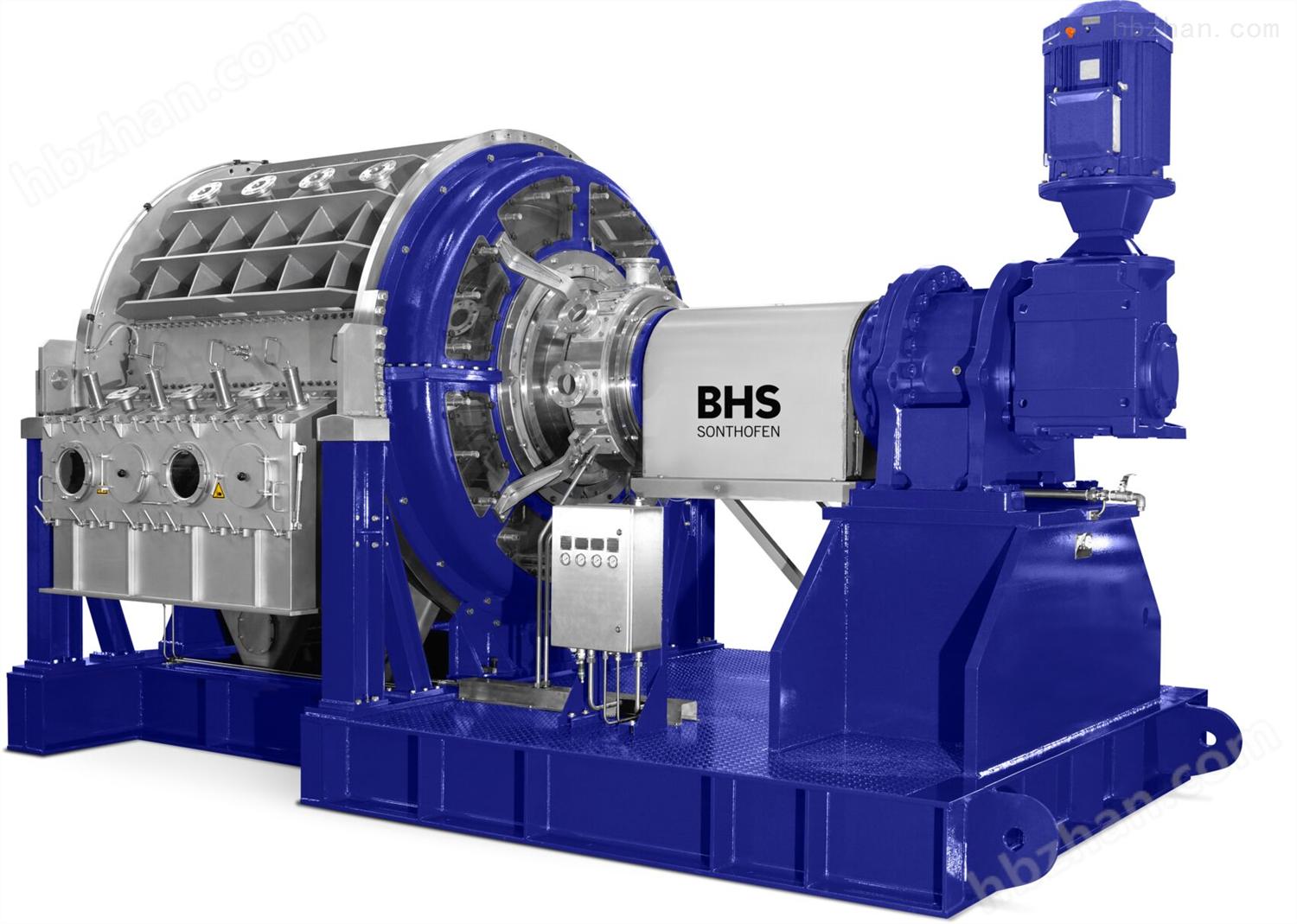

| 3 | Neutralization washing | The material is then transferred to the slurry mixing tank and the neutralization tank, and the material in the neutralization tank is neutralized. After reaching the appropriate pH value, the slurry is transported to the preheated and cleaned BHS washing machine through the washing feed pump. After the first stage of steam filtration, the first/secondary washing water washing, and the second stage of steam filtration, a qualified filter cake is formed and enters the next stage of the process. The mother liquor of the first stage of filtration has a high salt content and enters the wastewater tank, which is sent to the wastewater station for biochemical treatment; the mother liquor of the second stage of filtration has a low salt content and enters the reuse brine tank, which is used as water for discharging and flushing of its affiliated pipelines; the high-pressure washing water return water for cleaning the BHS screen enters the reuse brine tank and is recycled for washing. | BHS filter press: 1. Energy saving: less steam, water and electricity consumption, saving 50% compared with the old filter press. 2. Product: good water and ash control effect, reaching the domestic leading level. 3. High degree of automation control, reducing the number of personnel operations. |  | |||||||||

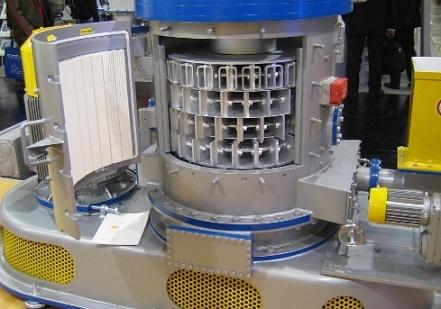

| 4 | Granulation | According to different specifications, the fine materials after granulation, drying, crushing and screening will directly enter the high-viscosity semi-finished product warehouse, and the coarse materials will enter the air flow mixer after secondary crushing. The materials are mixed in the mixing kettle according to the material ratio, and the samples are transferred to the packaging warehouse after passing the test. | Czechlin crusher: 1. High crushing efficiency and uniform particle size distribution. 2. Stable operation and low maintenance cost. |  | |||||||||

| 5 | Package | Packaging: According to the product index, the required materials are transported to the packaging warehouse by air. After being screened by the unloading forward and reverse dragon and the vibrating screen, the materials enter the automatic packaging machine for packaging and storage. | Automated valve bag packaging machines, conveyor lines and vertical warehouse systems. |  | |||||||||

| Liquid Phase Method | Features: This method has low reaction efficiency, good product quality, and easy control of substitution degree and performance, but it requires the use of special solvents, the cost of solvent recovery and treatment is high, and it has high requirements for production equipment. |

| Gas phase method | Features: This method does not require the use of solvents or diluents, the reaction process is simple, the production cost is low, the production capacity is high, the product substitution degree and uniformity are better, and the degree of automation is high. |